In Our Image - Case Study

Scroll down to see the process from start to finish.

In Our Image Workshop

The workshop where all the manufacturing took place.

Step 1Original Maquette

Artists Maquette showing lines which would eventually be the metalwork.

Step 2Original Former of In Our Image

The full size polystyrene former in its basic form - this was used as a base to build the framework around.

Step 3Former covered in plaster

The polystyrene former first had to be covered in plaster to reduce fire risk when welding.

Step 4Maquette & Plaster model

Artist's maquette next to polystyrene former to give idea of scale.

Step 5Design transferred to model

The artist transferred all the lines from the maquette using string onto the full size former.

Step 6Metalwork following design

Initial stages of metalwork being fitted around former

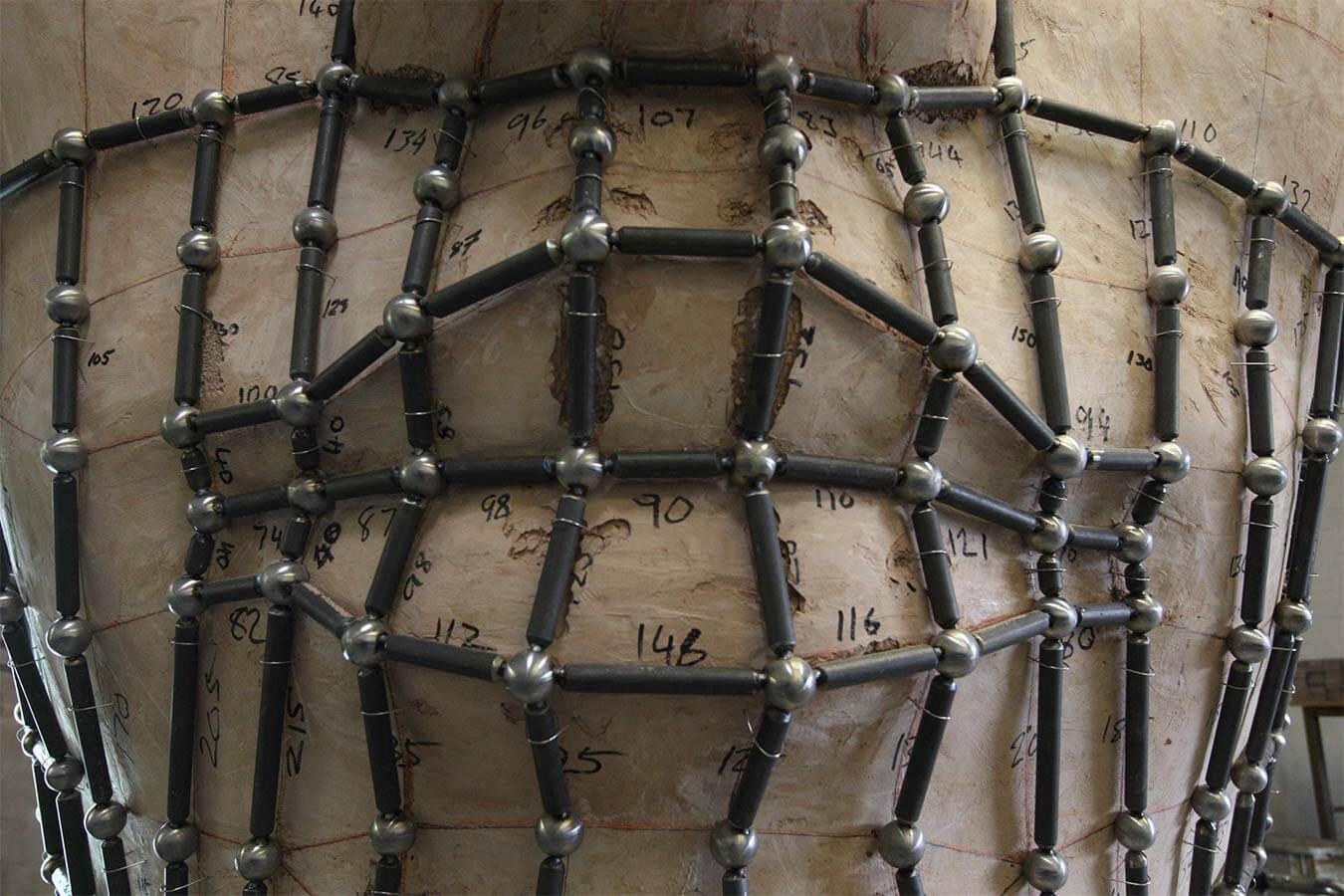

Step 7Metalwork showing individual dimensions

Close up detail of metalwork. You can see from the measurements written on the plaster how much detail each piece required. Every length of tube or bar was a different measurement and each section was joined using a metal sphere which had been specially manufactured from solid bar. The welding for each joint had to be Tig Welding to enable NDT testing to be undertaken with confidence once the structure was complete. Each joint involved at least 9 runs of weld making this a very time consuming process and meant that over 3000 welded joints were required. Each welder undertaking the work had to be tested on each particular joint he was welding and on each type of weld eg fillet weld, butt weld etc. Samples of each welded joints from every welder were also sent away to be tested before manufacture could take place and a welding procedure written up for every size of material and type of weld.

Step 8Models for the figures

The figures on the sculpture were based on some of the craftsmen who undertook the work. The artist photographed them whilst working and then enlarged the shapes which were cut out in metal and welded to the finished structure. Once again the welds used to join the figures to the structure had to be tested and the complete work NDT tested.

Step 9Head framework

Once the metalwork on the former was complete we had to remove the polystyrene from inside the sculpture leaving only the metal framework.

Step 10Shoulders framework

The sculpture was manufactured in three sections, the head, shoulders and legs. This picture shows the shoulder framework which had been brought outside in order to be lifted into he outdoor workspace and then joined to the head section.

Step 11Shoulders lifted outside of workship

The shoulder framework being lifted into the outdoor workspace. We used local company Ross & Wright for all the lifting during the construction phase.

Step 12Lifting head outside of workshop

The head framework outside ready to be lifted into the outdoor workspace.

Step 13Lifting head into outside work area

The head framework being lifted into the covered workspace where it was joined onto the shoulders using welding procedures which had been tested both on the joints and the welders carrying out the work.

Step 14Lifting head and shoulders

The head and shoulders are now joined together and ready to be lifted onto the transport to be moved to site and joined to the legs which have already been manufactured and installed.

Step 15Families and friends gather to watch lift

Families and friends gathered to watch the initial lift at our factory.

Step 15aLoading on to wagon

Head and shoulders lowered onto transport. We used specialist transport company GCS Johnson who gave us total confidence in their ability to transport such an unusual load.

Step 16Head & shoulders on wagon

Safely on the transport being secured ready for the journey.

Step 17Ready to roll

And we're off - a momentous occasion after all the months of hard work to finally see this huge sculpture being transported to its new home.

Step 18On Lorry

The view from the new site as the sculpture makes it's way along the road.

Step 19Arrived at site

Now getting ready to be lifted from the transport and secured to the lifting frame which was manufactured by Aycliffe Fabrications. We used Hewdens Crane Hire for the site lift.

Step 20Lifting in to place

Now for the real test - lowering the head and shoulders onto the legs which have already been concreted into place.

Step 21Colin, John Chris and Dave

Colin Henderson (Estimating & Technical Manager), John Flanagan & Chris Parkin (Senior Tradesmen) and Dave Mann (Production Manager) watching their months of hard work being lifted into place on site.

Step 21aColin,John & Chris

Colin Henderson (Estimating & Technical Manager) John Flanagan & Chris Parkin (Senior Tradesmen) waiting patiently for the lift to be completed so they can finalise the installation.

Step 21bDave & Christine watching

David Mann (Production Manager) and Christine Bewley (Director) watching apprehensively as months of work is in the hands of others being lifted into place.

Step 21cLowering on to legs

Of course it fits perfectly - we are experts after all.

Step 22Dave & Christine of course it fits

David Mann (Production Manager) and Christine Bewley (Director) delighted that finally all the months of work are in one place successfully.

Step 22aHead from cherry picker

A view from the top of the cherry picker - this is the view the 'Head' watches over at the entrance to Aycliffe Business Park.

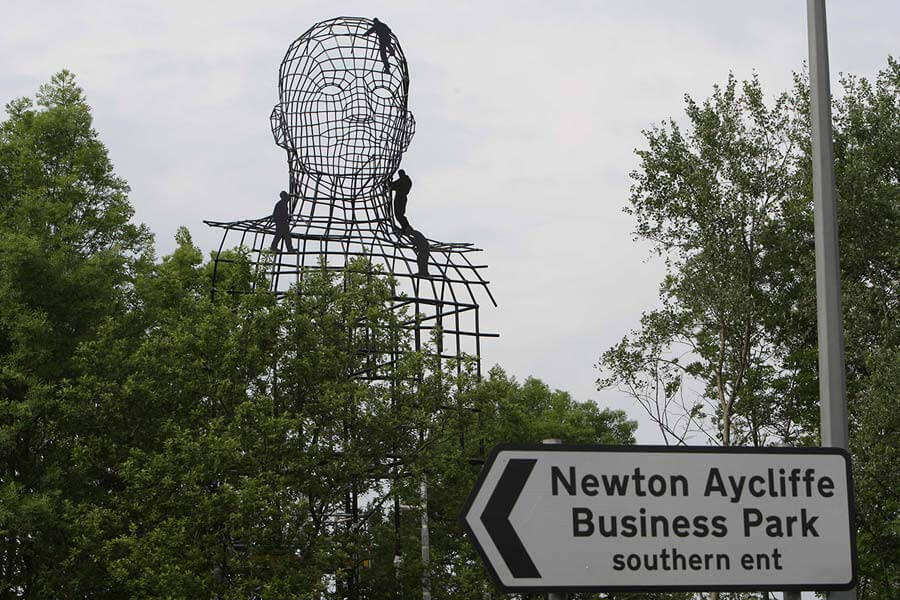

Step 23The final sculpture

Finally in place 'In our Image' settles into its new home at the entrance to Aycliffe Business Park.

Step 24Families & friends at site

It was a real family event as all our familes and friends gathered to watch the final installation.

Step 24aHead with ABP sign

As the trees grow around the sculpture only the head and shoulders are visible which was exactly as the artist intended.

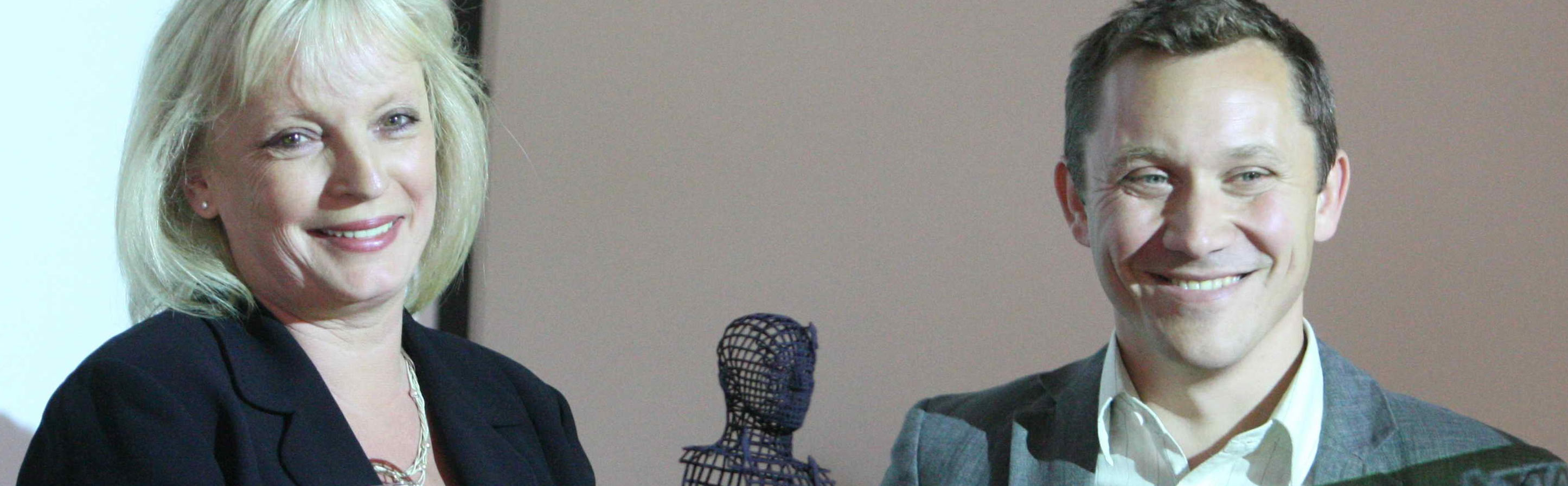

Step 25Joe presenting CB with model

Artist Joseph Hillier presenting Christine Bewley (Director) with 3D model of 'In Our Image'.

Step 26